You can read about all kinds of

things people do to power their hot wire foam cutter including things like running 110V

through a light bulb in series with the foam cutter, battery chargers, dimmer switches,

Variacs, "wall warts", batteries, and so on. There are ways that work, ways that don't, safe

ways, and unsafe ways, okay ways, and better ways.

Anytime you have the potential of

applying 110V to your foam cutter, it is unsafe. Using just a dimmer switch or just a

Variac

means that if you turn the knob too far, you can have 110V applied to the wire. If that

happens, you will either burn out your dimmer or Variac or vaporize your wire or both and

that could also cause a fire. In addition, if your were to accidentally touched the wire or

any exposed terminals, connections, or wires on EITHER the input side or output side, you

could get a shock or if the conditions were exactly wrong, you could die from cardiac

arrest. A fuse, circuit breaker, or GFI on the input side might help but will not guarantee

the negative results above.

If you have a low voltage

requirement such as is needed for shorter or thicker wire, you will not be able to get a low

enough voltage with a dimmer switch or Variac anyway. There is a limit to the low voltage

they can put out.

The proper way to power

your foam cutter

is with a

TRANSFORMER

A transformer reduces the voltage

to a lower level so you can't apply line voltage to your foam cutter with the accompanying

hazards. A transformer swaps voltage for current. Most foam cutters take a moderate current

and low voltage. For example, with a 12V transformer, you put in 120V and you get out 12V.

That is a ratio of 120/12 or 10:1. The current is increased 10 fold and the voltage is

reduced 10 fold. If your foam cutter requires 3 amps, then you are only putting in 1/10 of

that or 0.3 amps into the transformer which is slightly more than a 40 watt bulb. The

voltage goes down, the current goes up, no shock potential on the output side of the

transformer or at the nichrome wire,

You can design your foam cutter so

that all you need is the right transformer that puts out the right voltage and is big enough

to output the current you need. (see the Calculator page and the Transformers page. That is

the simplest solution. Note that the green C-shape is representing a bow type foam cutter

with the nichrome wire stretched between the two ends. Any type hot wire foam cutter can use

the same type power supply as the rest of this article describes.

The problem with this overly

simplified design is that it has no protection for the transformer against short circuits

and no way to adjust the voltage (and so the current or amps) so you can't adjust the heat

for the optimum foam cutting temperature. You can calculate the proper wire gauge and length

and it will work fine but if you ever want to change the wire size, wire length, or

temperature, you have no way to change the voltage to match it.

The best design will add a dimmer

switch and fuse, breaker, or GFI to the circuit above and will use the safety ground wire

from the wall plug and attach it to the transformer housing and also to the foam cutter

frame if it is metallic.

With these components in your

power supply, you have all the necessary features for safe and adjustable features to power

your hot wire foam cutter. The dimmer switch allows you to adjust the voltage from a low

value to the maximum rated output voltage of your transformer, the transformer steps down

the voltage and steps up the current, the fuse protects all your components against

accidental short circuits, and the safety ground connections protects against shock in the

case of a component or wire failure.

Dimmer Switches

There are a lot of different kinds of dimmers and fan controls. First, you don't need a

fan control. You can't use a light dimmer to control a fan because you will damage the

motor but a hot wire foam cutter is most similar to a light bulb -- just a hot wire, but

not hot enough to glow. Fan controls are more expensive because they have additional

circuitry in them. Don't waste the extra money on a fan control.

There are two main

manufacturers of dimmers, Lutron™ and Leviton™. There are many different types of dimmers,

fluorescent, incandescent/halogen, single pole, 3-Way, 600Watt up to 2000 watt, white,

ivory, gold, ganged, rotary on/off, push on/off, combos, etc. Fortunately, the simplest

and cheapest is also the best for hot wire foam cutters. What you want is a 600

Watt, Single Pole, Rotary On/Off dimmer, your choice of white or ivory knob. The

Lutron model number is D-600R-WH (white) or D-600R-IV (Ivory). The Leviton model is 6602-I

(Ivory), 6602-W (White) or 6602-IW (has both colored knobs).

The most common type of dimmer you will find in your local lighting or hardware store

is called a pre-set. What this means is that you can set the amount of dimming and then

leave it there so when you turn the light on or off, you don't disturb the setting. This

is either done with a separate button (used with slider dimmers) or using a push on/off

action (used with rotary dimmers). You likely will not find a rotary on/off at a local

store, they will all be the push on/off style because that is the most popular by far in

the home user market. Jacobs Online offers both types on eBay.

If you use the push on/off rotary type, then you won't be able to tell if your foam

cutter is on or off just by looking at it because the knob switch is a toggle. It is

always out. You push it in to turn it on if it is off, you push it in again, to turn it

off if it is on.

If you use the rotary on/off type dimmer, you know it is off because it is all the way

counterclockwise. It clicks when you turn it off the same as old style radio volume

controls that turned off the radio when you turned all the way to the left. If you knob

has no marks to indicate where it is currently set, you can easily put a mark on it with a

fine tip felt pen or a scratch mark or what ever you want. You won't know where you had it

last but you can also put a mark on the cover plate for your preferred setting so you just

turn it on and turn to line up the two marks.

IMPORTANT: A dimmer does not turn on

until it is turned up to about 50%. After it comes on, you can then turn it down to about

15% or 20% of its full output. It also does not turn on until a certain amount of current

is flowing through it. Just hooking up a transformer to its output does not cause enough

current to flow through it to turn it on regardless of how far you turn the dimmer up. You

MUST have a load on the dimmer. A load is an electrical term for a device that draws

current. You could connect a light bulb to the dimmer or your nichrome wire to the output

of your transformer connected to the dimmer and then the dimmer will turn on. If you only

attach a volt meter or multimeter to the output of the dimmer or transformer but nothing

else, your voltmeter or multimeter will register only a slight voltage. Hook up your

transformer and nichrome wire first and then clip your voltmeter to the two ends of the

nichrome wire and you will read the output voltage. Be sure your meter is set to read AC

voltage.

Adding An Indicator Light And

Separate On/Off Switch

If you are using a push on/off

dimmer, each time you push the knob, you can be changing the preset position a little. It

tends to always be in the clockwise direction for some reason. Of course, if you mark the

optimum position, you can always readjust the knob to the correct position.

Another enhancement, especially if

you are using the push on/off style dimmer but also just as an enhancement is to add a

separate on/off switch and indicator light as shown below. The first diagram shows the light

between the light switch and dimmer switch. In this configuration, the light will be on full

bright any time you turn the power switch on but will not indicate whether there is power to

the foam cutter or not. The advantage is that if the light is off, you know there is no

power anywhere in the circuit downstream of the switch. That way you can leave the dimmer

switch on and at the desired position all the time and not change it and just turn the power

switch on and off separately.

The indicator light is just a

standard small 110V incandescent bulb. It can be a standard 40 watt bulb or a smaller

wattage appliance bulb or better yet, a night light that uses a small Christmas tree type

bulb. You can add a standard household outlet in a box between the on/off switch and dimmer

switch or you can put both the switch and the outlet in a double box with a combo cover

plate and then just plug the night light into the outlet.

The second configuration shown

below is with the indicator light between the dimmer and the transformer. In this case, the

light bulb will give an indication of the proportion of the voltage going to the

transformer. The advantage is that it shows whether the dimmer switch is on or off which is

handy if you are using the push on/off type dimmer switch. If the dimmer switch is set too

low, it may be hard to see if the light is on at all but in that case, there isn't much

voltage coming out of the transformer, either. You could even put a light in both positions

if you wanted to.

As in the configuration above, you

can add a power outlet and plug a night light into the outlet. In this case, you could put

the dimmer switch and outlet into a double box with a combo plate. This is also handy

because you can then put a standard 110V plug on the input side of the transformer and then

plug that into the second wall outlet. If you wanted to change the transformer later or even

if you wanted to use two separate transformers for different foam cutters, you just unplug

one and plug in the other. You could mount two transformers on the same board with the

dimmer, switches, and outlets.

Checking the voltage and/or

current.

You can monitor either the voltage

or the current from the output of the transformer. A clamp on ammeter can be used to check

the current flowing through your foam cutter nichrome wire by clamping it around either of

the wires coming out of the transformer since the output is AC. If you have a panel type

ammeter, you can splice it into one of the output wires. You can check the output voltage by

clipping the alligator clips or touching the test probes to the two output wires.

It would be nice to have both a

digital panel voltmeter and digital panel ammeter mounted in a metal box along with the

other components for a nice self-contained unit but there are two drawbacks. Panel meters,

even analog ones, are expensive. Also, panel meters have only one range so if you are

working in the 1 or 2 amp range, the panel meter would not be the same as one for one in the

10 amp range. It is the same with the voltmeter, if you are working with 3 or 4 volts, it

would not be in the same range as a voltmeter for a 12-24 volt range. Handheld multimeters

and clamp on ammeters have ranges so one instrument can be used for any range.

Packaging your Power Supply

You can mount your light switch,

dimmer switch, plug-in for the output from you dimmer switch and your transformer on one

board. You could then put a plug on your input wires (primary) to your transformer and plug

the transformer into one outlet and your power indicator light into the other as mentioned

above and you will have a nice neat package. The diagram below shows banana jacks and a

panel mounted fuse holder in a blank cover plate on the left side. The output from the

transformer goes into the left side and attaches to the banana jacks. The foam cutter would

then be plugged into the banana jacks. The 110V plug and cable also goes into the box on the

left side, the hot side goes to the fuse holder.

You could also mount everything in

a metal box with rubber feet and a carrying handle for an even nicer package. Metal boxes

heavy enough for the transformer can be kind of expensive, though. It is also difficult to

find just the right box. If you Google electrical box or utility box or

device box, you will get the kind of boxes you use in house wiring to

mount switches and electrical outlets into. Google "Project Boxes" to

look for boxes.

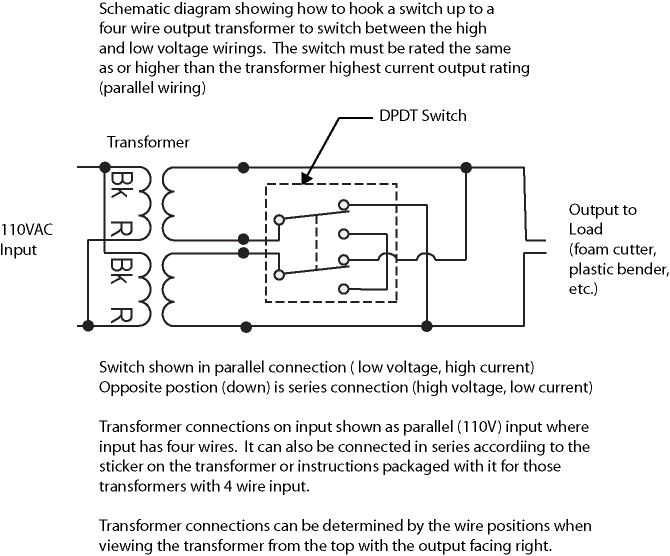

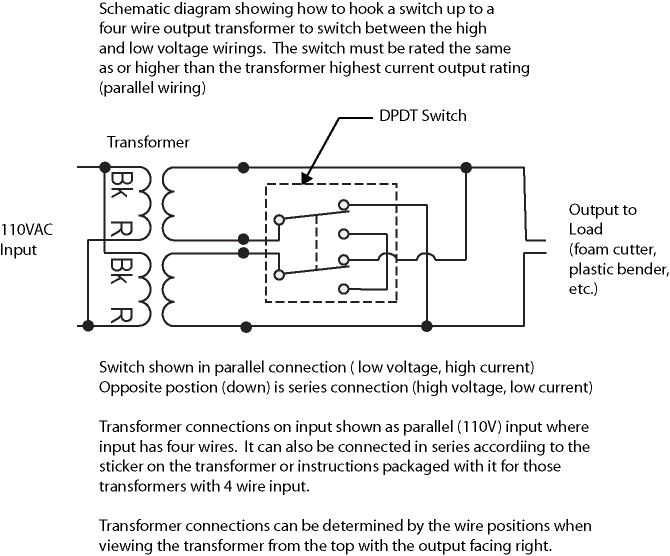

You can also add a DPDT switch to

switch between the low and high voltage outputs for four-wire output transformers.

Here is the schematic for how to wire it.