I recommend you read through the Transformer Info

(Understanding Transformers) page so you understand transformers better if you are not

familiar with them. The Power Supply Design page explains how to build a complete power

supply for a hot wire foam cutter after you have selected the wire and transformer.

This page combines information on how to choose both

the nichrome wire and the transformer for the power supply because the two go together--one

depends on the other.

Wire Measurement

Wire is measured in gauge. There are several

different gauge standards so it is common to use the decimal measurement instead of gauge

now. Nichrome wire and other non-ferrous metals use the AWG gauge standard, American

Wire Gauge, and this is the standard I use on my Web site but I also list the decimal

inches. The AWG is the same as B&S standard, Brown and Sharp. This standard is also used for

copper and aluminum wire so is the same gauge as is used for electrical wiring in your home.

Ferrous wire like iron and stainless steel wire most

commonly use the W&M, Washburn & Moen, wire gauge.

A comparison chart that shows the

decimal wire diameter and the associated gauge size in the SWG, BWG,

W&M, and AWG standards can be found here

http:/dave-cushman.net/elect/wiregauge.html.

For the reverse, showing the gauge number and the associated decimal

equivalent for the SWG and AWG standards can be found here

https://bsfixings.uk/resources/wire-gauge-chart/

As the gauge number gets larger, the wire size gets

smaller. AWG 40 gauge is hair fine while AWG 14 gauge is nearly as large as a

household wire clothes hanger.

What wire size should I use?

You can use any wire size you want to. Foam can

be and is cut with wire sizes from 40 gauge (.003" dia.) all the way up to 11 gauge (.091"

dia.). The most common size is 26 gauge. A short piece of 40 gauge wire has been

used with a 9 volt battery to cut very thin (.020") and narrow strips of foam for

air surfing walk-along gliders.

Two D cell batteries can power a 4" piece of 32 gauge nichrome wire in a small hobby hand

held foam cutter.

A 12 volt power supply will power up to 24" of 26

gauge wire at 800F or 17" to 1000F. This would include nearly all table top foam cutters which is the most

common type of foam cutter, and would include small bow cutters. This is why 26 gauge

is the most common. 24 gauge to 30 gauge has also been used for table top models.

16 gauge to 11 gauge is used for foam cutters to cut

shapes such as molding because they are stiff enough to hold a shape rather than being

straight. A 12" piece of 14 gauge nichrome wire requires only

3 volts but almost 19

amps. Larger diameter wires are also used for very long cutters such as 8 or 10 feet.

The Tension Factor

All metals expand with heat so the nichrome wire at

cutting temperature also expands and gets longer. Because of this, some method of

keeping tension on the wire is needed in hot wire foam cutters. This is usually

accomplished either with a springy frame that the wire is stretched between or a spring is

used. It is also conceivable that a weight could be used with the wire over a pulley.

Tension on the wire also helps keep it taut so when a little pressure is applied when

cutting foam, the wire stays fairly straight which is necessary for a good quality and

uniform cut.

Because of the need for tension, the smaller the wire

is, the less tension can be applied without breaking or permanently stretching the wire.

Using 40 gauge wire means very little tension is possible and it will be harder to keep the

wire taut when cutting. The longer the wire is, the more pressure needs to be applied

to the wire to keep it straight and taut. This is why as a general rule, the

longer the wire, the thicker it needs to be. There is no length vs. gauge size standard

since theoretically any size can be used at any length with the proper voltage applied and

current capacity of the power supply.

Gauge/Current/Temperature Relationship

The temperature of a straight wire in room temperature

calm air can be calculated. A given temperature will result in a specific current

flowing through a specific diameter wire. It doesn't matter how long the wire is, a

given current flowing through the wire will result in the same temperature. For

example, a 26 gauge wire with 3.2 amps flowing through it will result in

1000 degrees F

whether it is 2" long or 200" long.

The bigger the diameter, the more current is required

to heat it to the same temperature. For example, only 0.43 amps will result in

1000F in 40

gauge wire, but 18.8 amps is required for 14 gage wire. In addition, the larger the

diameter wire, the longer it will take to reach the equilibrium temperature.

The reason a strait wire reaches a given temperature

and stays there in calm room temperature air is that the current continues to produce more

heat as long as the current flows. At the same time, heat is being transferred away

from the wire to the surrounding air. The hotter the wire is, the faster the heat is

transferred away. The wire reaches its equilibrium temperature when the heat generated

is equal to the heat transferred away.

If you coil the wire, in a tight coil like in heaters,

transfer of heat away from the wire is reduced because there is more wire in a given volume

of air and so the wire will get hotter.

In the same way, a wire in contact with any other

material will change the rate of heat transfer away from the wire. If the material it

is in contact with is a good conductor of heat such as copper, the equilibrium temperature

will be lower because heat is transferred away faster. If the material it is in

contact with is a poor conductor of heat (an insulator) the equilibrium temperature will be

higher because less heat is transferred away. These situations result in complicated

heat transfer equations that are not easily solved. In this case, experimentation is

required to find the right wire and voltage to create the desired temperature.

When used in ovens, kilns and

enclosed heated areas, resistance wire will get progressively hotter as

the oven or kiln gets hotter if the voltage isn't changed. The

equilibrium temperature is based on the surrounding air temperature and

will be a fairly constant DIFFERENCE in temperature between the wire and

air temperature. So if you started out with 28 feet of 22 gauge

wire that was coiled such that the temperature was double that of a

straight wire, it would be around 1200F (316C), a difference of 1130F

between air and wire temperature, if the enclosure air temperature

started at 70F. It the wire would just be turning red at that

temperature. By the time you reached 1400F (760C) enclosure air

temperature, the wire temperature would be 1400F plus the difference of

1130F or 2530F. The wire would melt. For kilns and

other high temperature enclosures, the wire gauge, type, length, coil

dimensions, and voltage applied need to be carefully designed to limit

the wire temperature at the final achieved air temperature to be well

below the melting point, and the apparatus must be designed to turn off

at the target temperature or lower. This is not a trivial design

process and should normally be left to an engineer trained in heat

transfer and electrical design.

Current Created From Applied Voltage

As mentioned above, it doesn't matter what the length

of wire is, a certain current flowing through a given wire diameter will result in a given

temperature in free air. So how is that current created? A voltage applied

across the two ends of the wire create that current. The longer the wire, the more

voltage is required to create the same current. This is due to the difference in the

total resistance of the wire in different lengths.

Ohms Law

Ohms law is required to figure out the current and

voltage relationship. Ohms law states:

V = IR

V is voltage in volts (traditional E is used for

voltage and stands for electromotive force instead of V), I is current in amps, and R is

resistance in ohms. You can rearrange the formula to find the current:

I = V/R

From this you can see that is the resistance goes up,

so does the required voltage to get the same current. The resistance of nichrome wire

is specified in ohms per foot. The longer the wire, the more ohms resistance it has so

the longer the wire, the more voltage is required to push the current through the resistance

of the wire.

What Transformer Do I Need?

Power is calculated by the formula:

W = I2R or W

= VI

A transformer is usually rated in

watts or volt amps. For small transformers, they are essentially

the same and interchangeable. You need to know the power required

for your heated wire so you know what size transformer will be required.

To calculate that, you first decide what gauge wire you will use and

find the ohms per foot resistance of that wire. For example, 26

gauge wire has a resistance of 2.67 ohms per foot. If you are

using the wire to cut foam with, a good rule of thumb is to heat the

wire to just before it starts turning red which means just below 1112F

or 600C. 1000F is a good initial target temperature. If you are using a

dimmer or a variable voltage supply, you can turn the voltage up until

you can just barely see it turning red and then turn it down a bit. You

also need to know the length of the wire. Lets say you will use 2

feet. Now you can calculate the resistance, voltage, and power

requirements.

I = 3.2 amps (from the

calculator)

r = 2.67 ohms/ft

R = r*L = 2.67 X 3.2 = 5.33 ohms

V = IR = 3.2 X 5.33 = 17.1 volts

P = VI = 17.1 X 3.2= 55 watts

I = current in amps

r = resistance per foot of the wire in ohms

R = total resistance of wire

L = length of wire in feet

P = power in watts

The calculator actually calculates

all of that for you. This is just to explain how it does that. It does

not tell you what transformer you need.

To select the proper transformer,

go to the transformer page and look in the table at the top for a

voltage the same or higher than you (or the caclulator) calculated that

is the same watts (VA) or higher. The closest voltage the same or higher

is 18V. The same or higher VA is 100VA (50VA is too low). You have two

choices of 100VA transformers; either the 9V/18V or the 18V/36V. Either

can be wired for 18V. Click on the 100VA 9V/18V. Check the max rated

amps at 18 volts. It is 5.5 amps which is higher than what you

calculated so this will work. If you had chosen the next lower VA, the

50VA 9V/18V, the max rated amps at 18 volts is only 2.8 amps which is

below the 3.2 amps we need. You could use that if you used a dimmer with

it and turned the voltage down to about 14.7 volts which would give you

850F and 2.75 amps. That would still cut foam fine, just slower.

How do you know whether in this

case you should pick the 9V/18V or the 18V/36V? If you know you will

only use the length of wire you started with, it doesn't matter. If you

think you might want to use a shorter length in the future, get a dimmer

with the transformer so you can turn down the voltage. If you might use

much shorter, then be sure to get the 9V/18V so you can rewire it for

9V. You can also get a DPDT switch so you can quickly switch between the

9V and 18V.

If you think you might want to use

a longer wire, you can't just get the 18V/36V because when wired for

36V, you cut the max amps in half so that does not work. ALWAYS FIGURE

THE LONGEST WIRE YOU MIGHT EVER USE and chose the transformer that can

handle that at the temperature you will be cutting at. You can always

turn the voltage with a dimmer and can also switch to the lower of the

two voltages also if needed.

What if you really only wanted to

use a 50 watt (VA) transformer because of the size, weight, or cost? As

I already mentioned above, you can cut at a lower temperature. It isn't

that much lower. But you have another option. You aren't stuck with just

using 26 gauge wire. You can use a smaller gauge wire. Plug 28 gauge

into the calculator

keeping the temperature at 1000F and length at 24. You get 20.2 volts at

2.38 amps. Now you need to chose a transformer that can put out 24

volts. The 50VA transformer at 24 volts has a max rated amps of 2.1. Not

quite enough. Try 29 gauge. It gives 2.1 amps and 22.4 volts. That

works, barely, and you need a dimmer to turn the voltage down to 22.4

volts.

The difference in the sizes of

wire is the strength. Obviously, the larger the wire, the stronger it

is. If you are careful and don't try to push the foam through the wire

faster than it can cut, smaller wire works fine. You don't gain anything

by pushing harder anyway. These transformers are designed to only get

warm at the rated amps but it is still a good idea to select a

transformer that will be operating a little below the rated amps.

Transformers - Gauge And Max Lengths

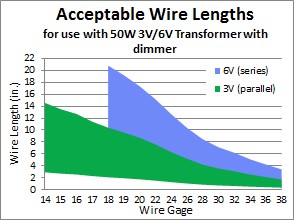

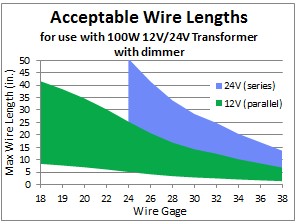

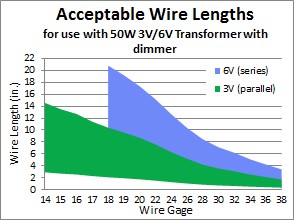

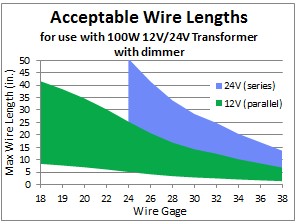

Below are a couple examples from

the 30

transformers I carry now. See the

transformer page where each transformer has its own graph. The graphs show the minimum and maximum length that each

transformer heat to 800F when used with a dimmer for foam cutting. For plastic

bending, the wire should be hotter and so the maximum lengths would be shorter. The

normal foam cutting temperature is 600F but figuring for 800F gives some room for

adjustment. All but one are dual voltages outputs so the lower voltage handles higher

current and so extends the range to larger diameter wires because the current capability is

doubled when the voltage is halved. The higher voltage handles smaller gauge but longer

wire. Dimmers do not go all the way to zero volts, they go to about 20%, so there is a

minimum wire length that can be use.

This transformer can be used with

short pieces of stiffer wire for shaped wire cutting.

|

This transformer is good for most

table top foam cutters and medium bows using 24-26 gauge

nichrome wire.

|